Discover Fab'Twill®

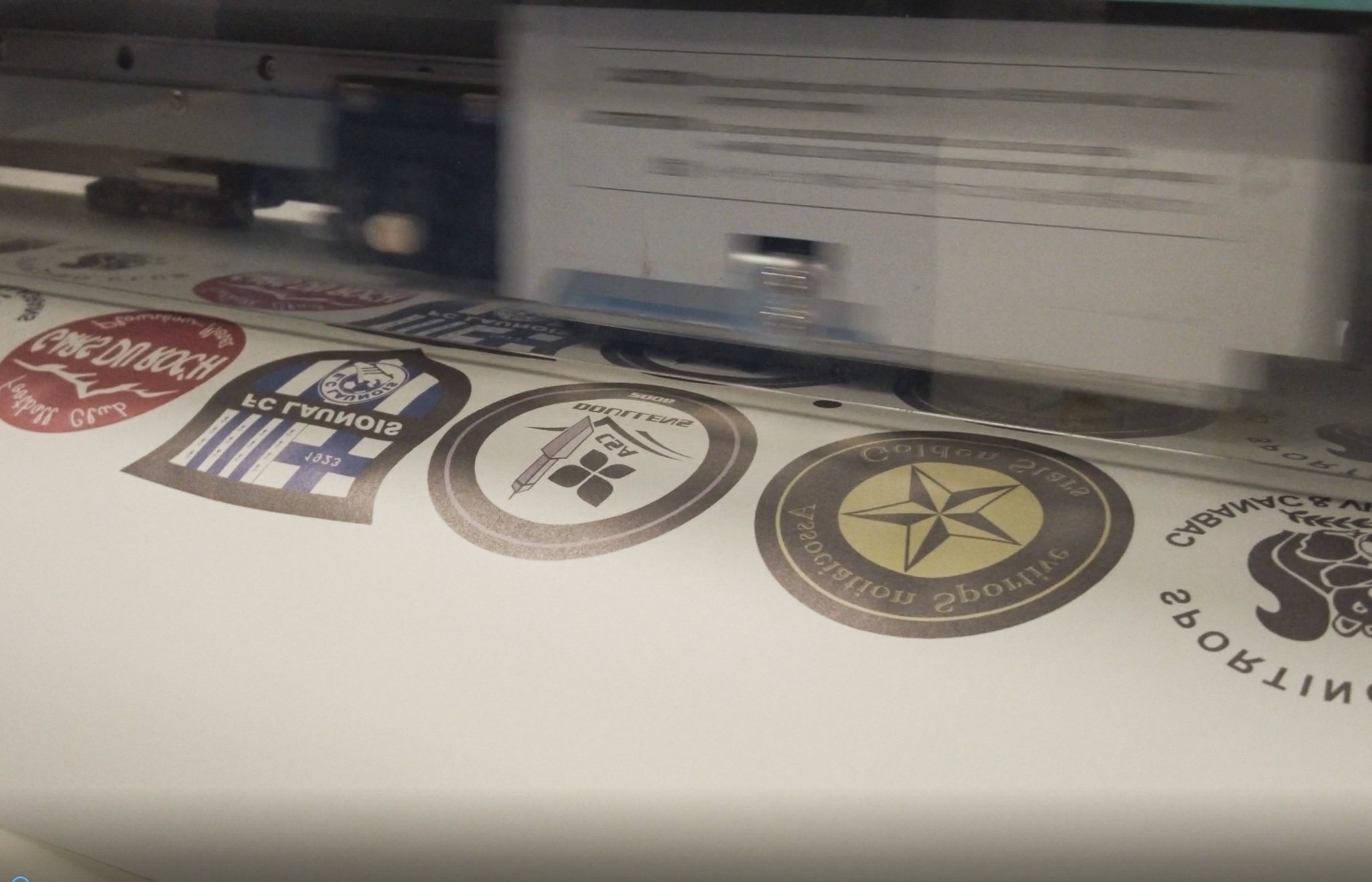

The entire process from dye sublimation printing to laser cutting and application of our unique heat transfer printable film is presented here.

Published : 12/07/2022 10:54:20

Categories : Events

Chemica has developed a unique product: a heat transfer printable film with a twill look and feel.

The textured feel of real fabric combined with the technicality of a printable media allows printing with sublimation inks to achieve vibrant colours, subtle colour gradations and superb contrast.

Made from a polyester base, this printable material is certified Oeko-Tex Standard 100 Class 1 and is very resistant. With a thickness of 230µm, it is easy to handle, laser cut and applied without tapping in one application. It is an ideal product to enhance the production of logos, crests, letters and numbers that will optimize your productivity.

Find out with us how to use FAB'TWILL® in our step-by-step guide below.

The entire process from dye sublimation printing to laser cutting and application of our unique heat transfer printable film is presented here.

Step n° 1 : Settings and preparation of the various tools

Here is a demonstration of the optimal use of a SEFA press.

- Switch on the press as soon as you arrive, well before it is used, to ensure a stable temperature

- Set the press to 4 bars, 200°C, 20s

- When the temperature is reached, make 3 vacuum presses on each plate to eliminate the humidity and bring them up to temperature.

Protective paper

- Press it at least once before use during a vacuum press.

- Always leave it on top of the hot press.

Sublimation paper

- Always leave it on top of the hot press (helps drying and eliminates moisture).

FAB'TWILL® printable

- Insert the blank sheets inside the press for 10s to 20s without pressure before preheating.

- Otherwise, always leave it on top of the hot press (to avoid thermal shock during preheating)

Step n°2 : Printing the image

Print your visual with mirror cut marks on sublimation paper

Step n°3 : Transferring the image using your Sefa Heat Transfer Press

- Preheating :

Check transfer parameters: 4 bar, 200°C, 20s

- Sublimation parameters: 4 bars, 200°C, 80s (1m20s).

Superimpose the sublimated paper format on the FAB'TWILL® printed side thanks to your cutting marks. The sublimation paper must be attached to the FAB'TWILL® using high heat resistant adhesive tapes on at least two opposite sides of the sublimation paper.

If the sublimation paper is not flat, apply another tape on a third side.

Press to transfer.

Lift the dye sublimation paper to remove it, being careful not to slip on the FAB'TWILL®.

Step n°4 : Laser cutting

Easily cut out your design using the cutting marks.

Remove the excess cut material.

In order not to burn the FAB'TWILL®, be careful to control your speed, your laser cutting speed settings.

Step n°5 : Application onto your textile

Remove the PET backing, place the visual on the textile as desired.

Protect it with a sheet of silicon paper.

Press at 160°C / 320°F / 20s

And that's it, your marking is finished.

Contact

Contact

Need some information?